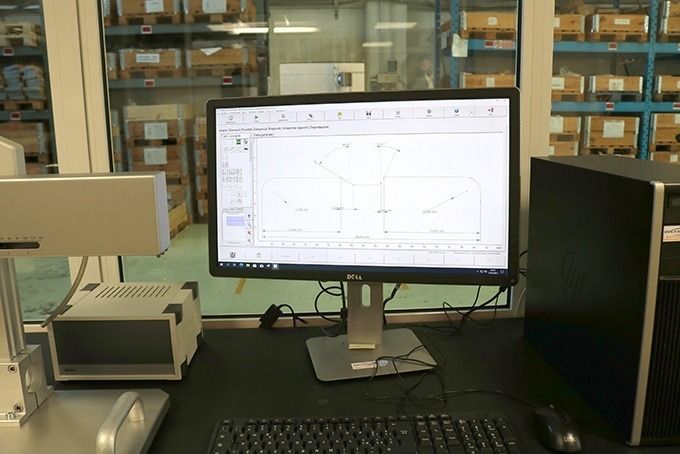

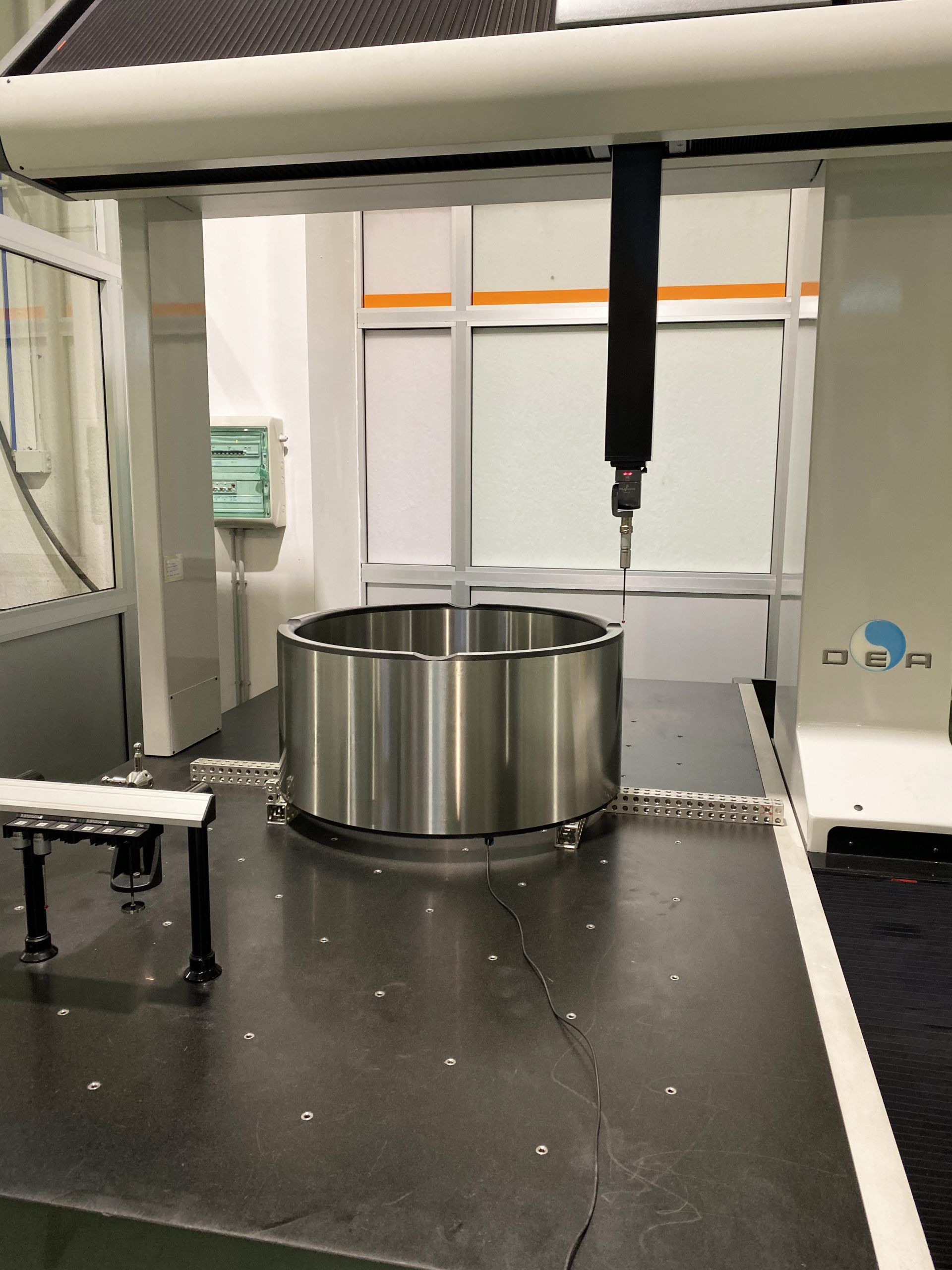

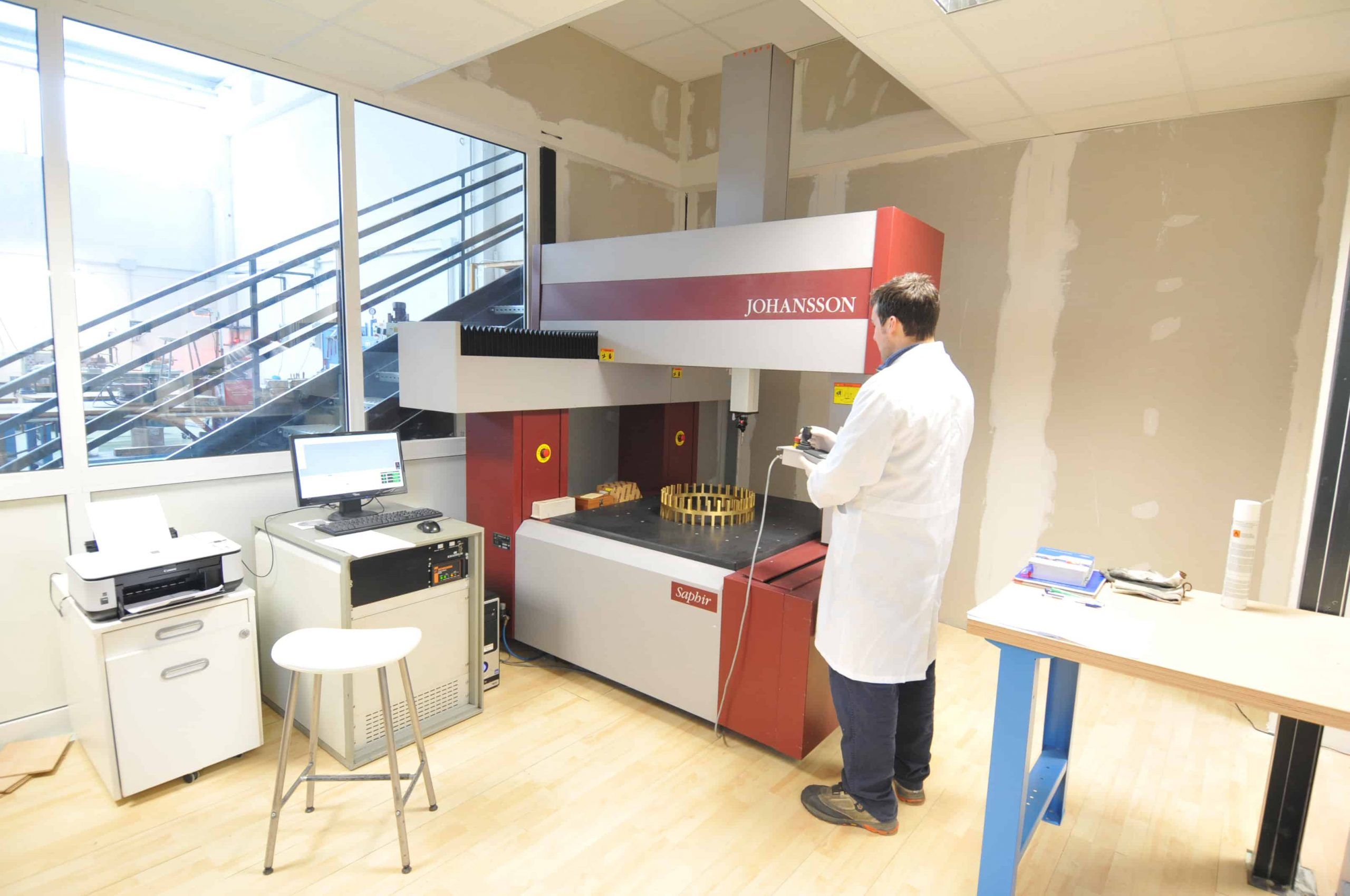

In the testing phase, for every lot of bearings' production, TTS technical staff uses a specific procedure that defines: what to check, the percentage of the items to be checked, what instruments to use and how to use them.

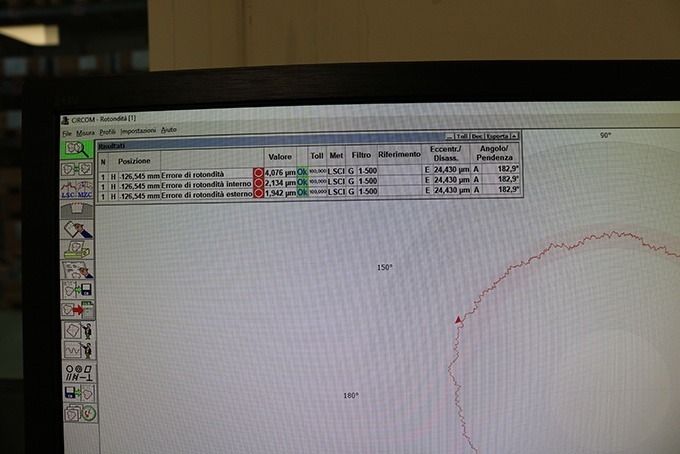

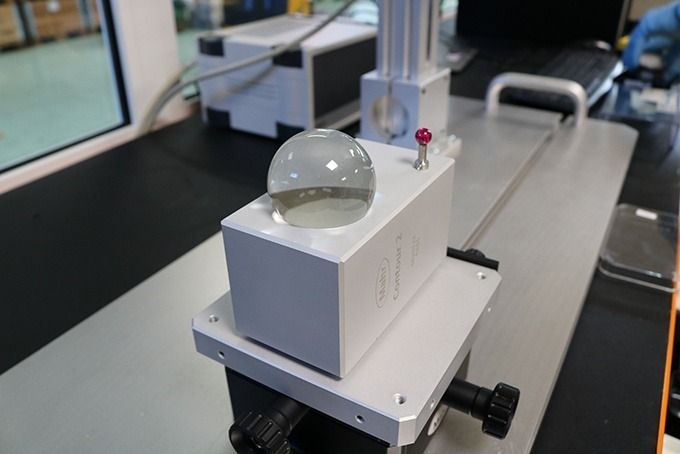

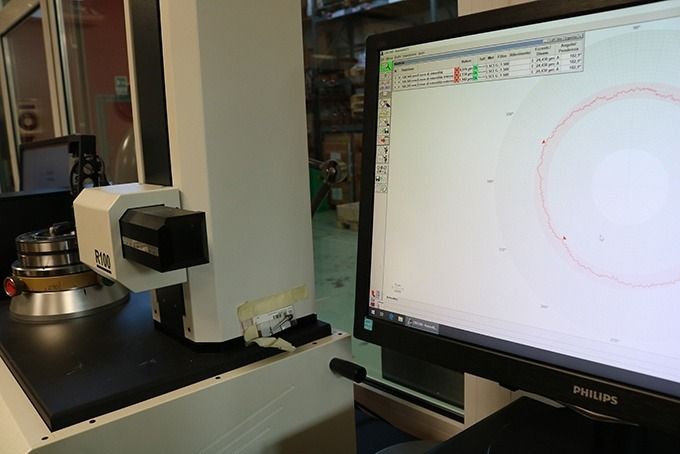

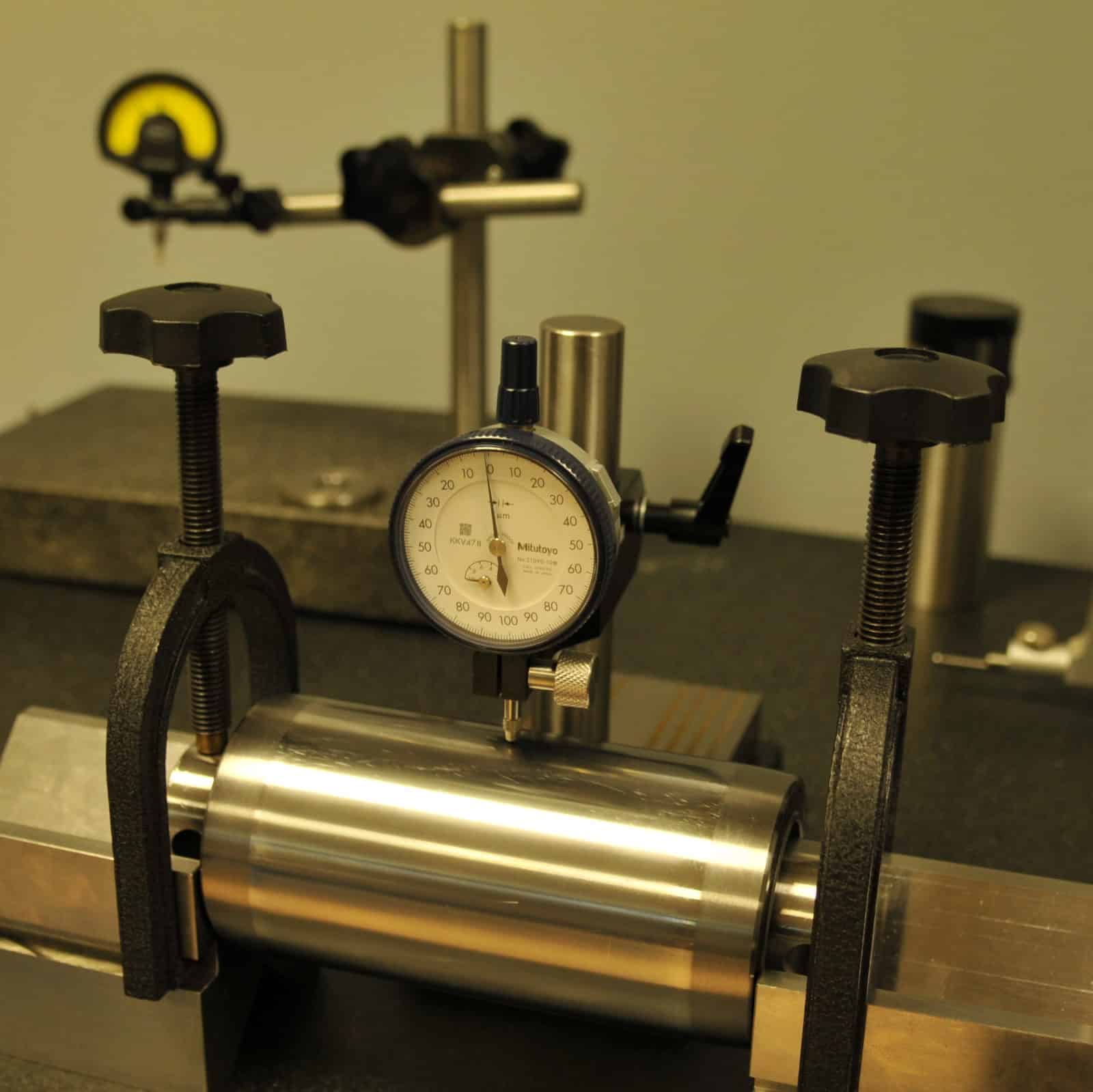

TTS standard procedure includes the verification of the accuracy in dimensions and shape, surface hardness, surface finish and other characteristics related to the specific type of bearing (eg: axial or radial clearance, run-out, etc.) and it can be implemented with other tests shared and agreed with the Customer during the order placement.

In addition to this, more detailed testings can be carried out, such as metallographic and micrographic analysis, hardness distribution analysis from the surface to the centre of material to check the quality of the raw material and heat treatment carried out.

The calibration of the instruments is carried out periodically by an accredited third party to guarantee its total reliability.

TTS standard procedure includes the verification of the accuracy in dimensions and shape, surface hardness, surface finish and other characteristics related to the specific type of bearing (eg: axial or radial clearance, run-out, etc.) and it can be implemented with other tests shared and agreed with the Customer during the order placement.

In addition to this, more detailed testings can be carried out, such as metallographic and micrographic analysis, hardness distribution analysis from the surface to the centre of material to check the quality of the raw material and heat treatment carried out.

The calibration of the instruments is carried out periodically by an accredited third party to guarantee its total reliability.