Insights – Slewing bearings

Meticulously designed & duly engineered by TTS

There are numerous bearings which can handle large radial loads & low axial loads and vice versa. But for cases where there are combined radial & axial loads with a tilting moment, slewing bearing is the solution. Their capability to handle combined loads, gives an immense advantage interms of lesser design requirements for the adjacent machinery and fittings.

Slewing bearings are capable of handling slow turning or slowly oscillating loads with combination of axial, radial & moment loads. Compared to traditional bearings, slewing bearings have wide rings and generally have holes distributed on the surface which are fixed to a structure. The slewing rings can be of four-point contact bearings and crossed roller bearings.

Four-point slewing bearings prove to be exceptionally advantageous where the application requires low accuracy and rigidity, for example in wind turbines or construction machinery. On the other hand, for applications with high requirements of axial and radial accuracies and rigidity, as in robots, machine tools etc the crossed roller bearings are preferred. These bearings can be provided with seals on both sides. These seals can be made of either NBR, FKM or metal seals depending on the application. Both these variants can have teeth on the inner ring or outer ring or can be without the teeth which purely depends on the application.

TTS understands every customer needs carefully and considers their interest in producing a world class product, 100% made in Italy.

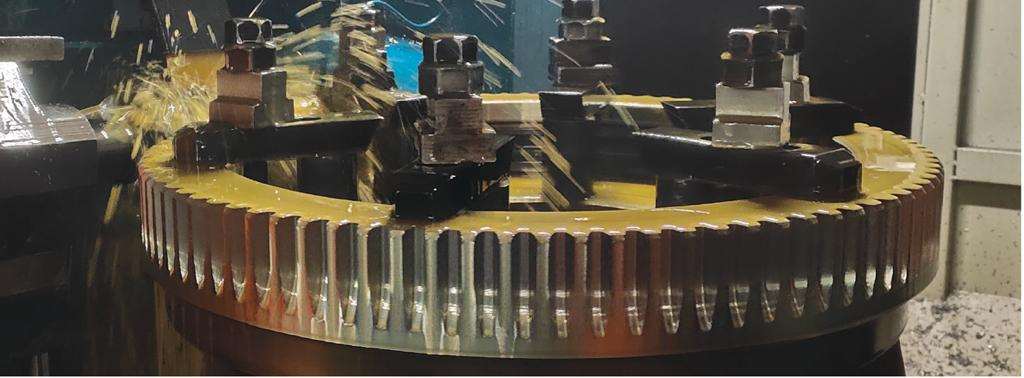

TTS can produce slewing bearings up to 2000mm external diameter using European material of C45 or 42CrMo4 with latest generation of machine tools.

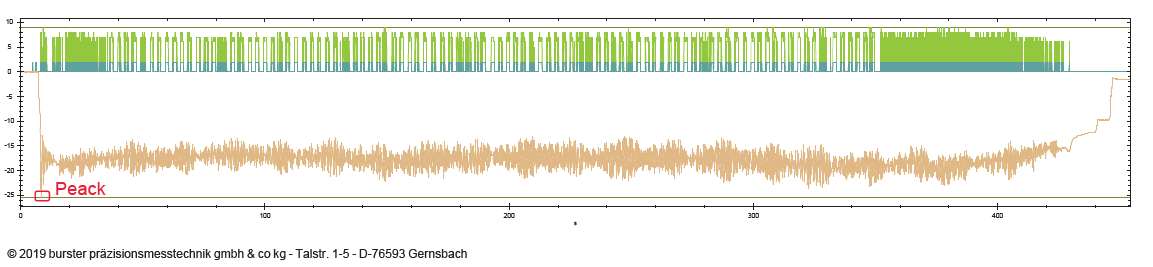

Before delivering to the customer the quality control department of TTS ensures that, the bearings are produced exactly according to the parameters agreed in the drawing. As in Figure 2, TTS has invested in test bed for measuring the starting torque. The starting torque is measured without load and with load upto 4500Kg applied on the bearing. In both the cases TTS ensures that the starting torque is as agreed with the customer.

TTS uses latest instruments and software to measure the starting torque. A sample report of starting torque of TTS bearing can be seen in Figure 3. Apart from starting torque, TTS has stringent standards to measure the axial & radial runouts and axial and radial clearance. For measuring other standard dimensions CMM is used for the measurement.

TTS has incorporated various steps to fulfil the project from start to end. For any further clarifications and enquiries please visit our contact us page.